Eco-Friendly Furniture in Rajasthan: The Rise of Bagasse Particle Boards

Sustainability is no longer just a buzzword—it is transforming every sector, including the world of furniture. In India, and particularly Rajasthan, eco-friendly furniture is fast becoming the standard for conscious consumers and forward-thinking manufacturers. As the state embraces innovative materials and green policies, one star material is rising above the rest: bagasse particle boards. This detailed guide explores how bagasse is reshaping Rajasthan’s furniture landscape and why this trend matters for the environment, artisans, and end customers.

The Environmental Cost of Traditional Furniture

For decades, India relied heavily on wood-based furniture, driving up demand for timber and pressurizing forests. With India’s furniture market projected to climb from $30.6 billion in 2025 to $64.1 billion by 2032, this growth brings a significant environmental burden—a surge in deforestation and carbon emissions. The cost of timber has increased by 25% in recent years, while rising global concerns about climate change are forcing both businesses and consumers to seek alternatives.

Traditional medium-density fibreboard (MDF) and solid wood furniture, though popular for their aesthetics and strength, contribute heavily to greenhouse gas emissions. Every ton of timber harvested means lost biodiversity and diminished carbon sequestration capacity. As the government tightens regulations and pushes for sustainable alternatives, the need for innovation in furniture materials is stronger than ever.

Bagasse Explained: Transforming Waste into Wonder

Bagasse is the fibrous residue left after extracting juice from sugarcane. India, the world’s second-largest sugarcane producer, generates millions of tonnes of bagasse annually, much of which goes unused or is burnt, contributing further to air pollution. In Rajasthan, bagasse is especially abundant, making the region ripe for eco-friendly transformation.

Historically, bagasse was used as fuel, fodder, or compost, but scientists and entrepreneurs have unlocked its potential for particle board manufacturing. Instead of letting this resource go to waste, Rajasthan’s manufacturers are turning it into a raw material for sturdy, attractive, and sustainable furniture.

Bagasse Particle Boards: Manufacturing & Industry Trends

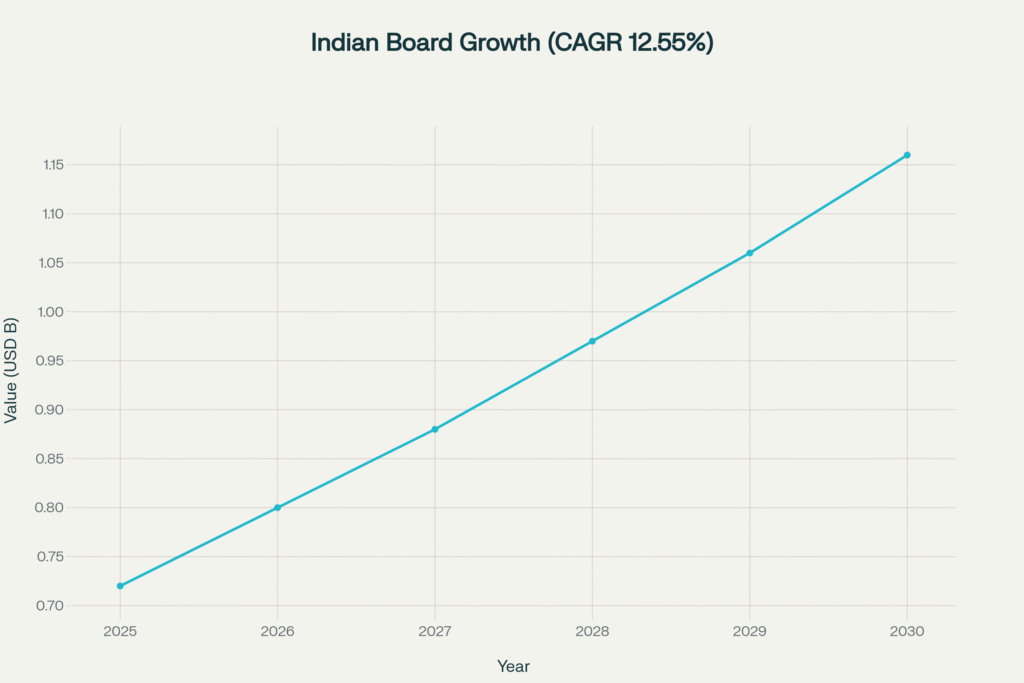

Bagasse particle boards are engineered sheets made by compressing bagasse fibers with resins and adhesives under high heat. This process uses agricultural waste rather than wood, dramatically lowering the product’s carbon footprint. The Indian particle board market, valued at about $0.72 billion in 2025, is expected to reach $1.16 billion by 2030, growing at a healthy 10.15% CAGR.

Market Growth Visualization:

While wood commanded 61.86% of the nation’s particle board market share in 2024, bagasse-based boards are forecast to accelerate at a 12.55% CAGR, outpacing all other materials.

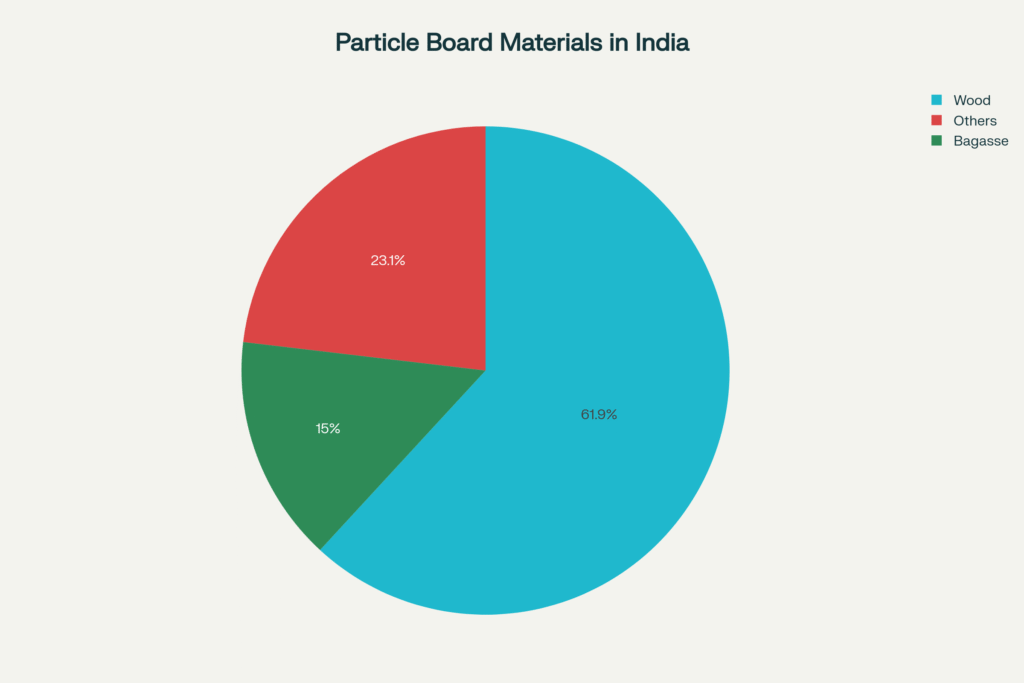

Material Share Table of Indian Particle Boards (2025)

| Material | Market Share (%) |

| Wood | 61.86 |

| Bagasse | 15.00 |

| Others | 23.14 |

Material Share Pie Chart:

Eco-Friendly Benefits of Bagasse Particle Boards

Opting for bagasse particle boards is a win all around:

- Reduced deforestation: Every tonne of bagasse used equals a tree saved. This preserves forests and wildlife ecosystems.

- Lower carbon emissions: Bagasse boards emit much less CO₂ during production, and their manufacturing often uses energy from renewable sources.

- Waste utilization: Converts agricultural residue into high-value products, supporting a true circular economy.

- Compliance: Bagasse boards often meet export standards for low formaldehyde emissions, opening doors to EU and U.S. markets.

Bagasse-centric plants are compiling carbon-credit records to monetize greenhouse-gas offsets, helping cushion manufacturers from unstable market prices. University trials now show bagasse boards rival their wood and eucalyptus counterparts in strength and durability when produced on optimized presses.

Rajasthan: Sustainable Development, Policy & Industry Leadership

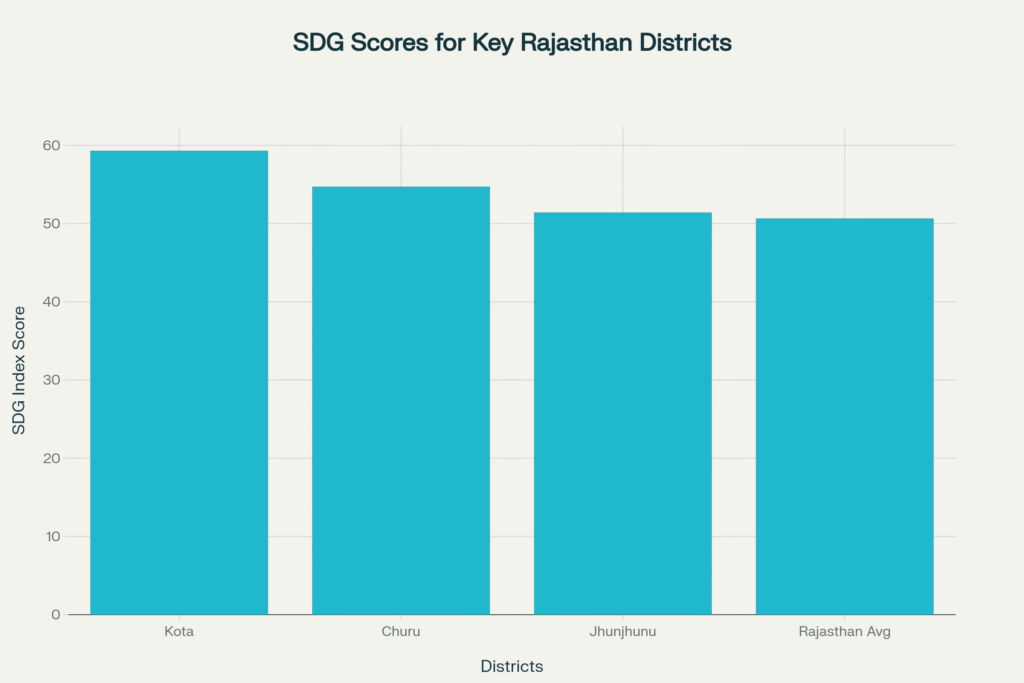

Rajasthan is a leader in sustainable development, supported by government incentives, targeted policies, and abundant supply chains. Districts like Kota, Churu, and Jhunjhunu score highly for sustainability according to the state’s SDG index. Kota, for example, achieves a score of 59.3, well above the Rajasthan average of 50.63.

SDG Index Scores Visualization:

Local manufacturers are pioneering new processes for cleaning and depithing bagasse, securing preferential contracts with exporters who prioritize green certifications. With the region’s sugar mills supplying raw material and the government championing sustainability, Rajasthan is poised for exponential growth.

Furniture Applications: From Urban Homes to Global Shores

Bagasse particle boards are fast replacing traditional wood boards in all types of furniture. Tables, doors, shelving, modular storage systems, and cabinetry are now built with bagasse boards—manufacturers report improved durability and consumer satisfaction. As urbanization accelerates, eco-conscious buyers in Rajasthan and beyond are showing a 40% increase in preference for sustainable furniture. Meanwhile, demand for modular furniture has jumped by 35% in 2025, reflecting the appeal of versatile, affordable, and green-labeled products.

Major furniture brands and e-commerce sellers are scaling up “ready-to-assemble” lines optimized for flat-pack logistical efficiency—a format well-suited for particle boards, which are lighter and more cost-effective than plywood.

Challenges: Costs, Scalability & Education

Despite strong growth, challenges remain. Production costs for bagasse boards have increased slightly (Rs. 2–3/sqft in 2025, according to industry sources). Market expansion depends on scaling up manufacturing technology and educating consumers. Some small mills struggle with resin price volatility and need more robust working capital to manage seasonal availability.

The Big Picture: Market Opportunity and Future Outlook

Eco-friendly furniture, powered by bagasse particle boards, is at the heart of India’s green transition. Furniture and cabinetry constitute over 62% of particle board usage in India, with both consumer and commercial sectors demanding sustainable options for homes, hotels, offices, and retail spaces. The eco-friendly furniture market itself is projected to soar from $54.57 billion in 2025 to $93.86 billion by 2032, representing an 8% CAGR.